Recently, I visited Shillong for a three day workshop, and on the third day, during a field visit to a village near Shillong, I came across three trucks carrying charcoal in gunny bags. Later, for the first time, I witnessed a traditional method of charcoal making.

Charcoal production through traditional earth mound method in the village near Shillong

Meghalaya is known for its rich biodiversity and lush green forests, facing a silent crisis. The ancient method of charcoal production in the state, though a means of support for many, is cause for several challenges such as forest denudation, biodiversity loss, and environmental degradation. The rise in demand for charcoal, fueled by establishment of charcoal consuming new industries, has led to the illicit felling and transportation of trees, threatening the forests that sustain communities and wildlife.

Unsustainable utilization of forests for charcoal production may be profitable at this point of time, but it will affect future generations by depleting resources, just as we are witnessing with climate change. The Western Industrial Revolution contributed significantly to global warming and climate change, the similar effect might be observed in the future and even more worse than that, if we continue on this path. Yes, economic development is essential, but we must strike a balance between economic growth and ecological conservation.

Coming to the issue of charcoal production-cutting and burning trees – is this the only method of producing Charcoal? And is it only a means of livelihood for communities? If sustainable alternatives exist, why can’t we adopt them?

An urgent question: Can Meghalaya find a sustainable alternative? This blog explores the impact of charcoal production on community forests, its consequences for the environment and local livelihoods, and potential eco-friendly solutions that can ensure both economic resilience and forest conservation.

What is charcoal?

Charcoal is a black porous solid material consisting mainly of elemental carbon, made from wood, bamboo, coconut shells, rice husks and bones. In many parts of the world, wood is commonly used raw material for charcoal production due to easy availability, relatively inexpensive, and efficient fuel source, especially in developing countries. Charcoal produced from hardwood burns cleanly and slowly, hence fetches high prices in the market. Whereas, softwood charcoal is light and porous, it burns quickly and is prone to breakage during transportation.

History of Charcoal Making in Meghalaya

Charcoal production in Meghalaya has a rich history intertwined with traditional industries, particularly ferrous metallurgy. Archaeological evidence indicated that iron smelting in Khasi and Jaintia Hills dates back around 2,000 years. These regions were major suppliers of iron to neighbouring places both north (Brahmaputra valley) and south (Sylhet plains). Charcoal was used as a fuel for running the iron industry. Meghalaya has emerged as one of the leading producers of charcoal in the country, as it produces a considerable quantity of charcoal. Charcoal is one of the important forest products of the state.

Contemporary times, certain communities in Meghalaya continue to engage in a sustainable way of production of charcoal, balancing economic benefits with environmental conservation. For instance, Mawbri village practices a structured approach to forest management by categorizing forest into three types; 1. Law adong: This forest is used only for water source protection, prohibiting farming and tree cutting. However, this forest can be used for collecting non-timber forest products (NTFPs) that do not harm the forest cover. 2. Law shnong: This forest permits controlled tree cutting for charcoal production. Households allowed for tree cutting for 3 years, after which the land is left fallow for 18 years to allow forest regeneration. 3. Bri shnong: It is similar to Law shnong but there is no specified time limit for its usage. Plots remain with households as long as they are utilized, ensuring continuous but regulated use.

However, charcoal production has become a business in several villages. The community land is gradually transferred into private ownership. The land is then leased to contractors for a certain number of years for producing charcoal. These greedy contractors exploit the lands unsustainably, cutting down young trees without allowing time for regeneration.

Key Species Used in Charcoal Making in Meghalaya

The native hardwood species such as Schima wallichii, Quercus spp., and Castanopsis indica (Indian Chestnut tree), Albizia lebbeck (Woman’s tongue tree) and Toona ciliata (Poma) produce the best quality charcoal that fetches good price. On the other hand, charcoal made from softwood includes Litsea spp., Stereospermum griffithii, Bombax ceiba, Bischofia javanica etc. fetches a lesser price compared to charcoal mode from hardwood. Two commercial bamboo species such as Dendrocalamus hamiltonii (Koko bamboo) and Melocanna baccifera (Muli bamboo) are also a source of raw materials for charcoal making. Nowadays, pine trees are also used in charcoal business in the West Khasi Hills District of Meghalaya.

Method of Charcoal Making in Meghalaya

Generally, Charcoal is made by burning tree stems and branches in a specially dug pit. It is then packed in sacks and sold in the markets. The quality of charcoal depends upon the tree species from which it is made. Charcoal production in Meghalaya is primarily done using traditional and semi-modern techniques, largely dependent on locally available resources and indigenous knowledge. The following are the commonly used methods:

| Method | Process | Advantages | Disadvantages | Sustainability |

| Traditional Earth Mound Method (Pit Kiln Method) | Wood is stacked in a conical or dome-shaped mound, covered with soil and leaves to regulate airflow. Small openings are left for slow burning (carbonization) over 4–7 days. | Simple,low-cost hence it is the most common and widely practiced method in Meghalaya, especially in rural areas. | Inefficient as much of the wood is lost as smoke.Leads to air pollution.Requires large quantities of wood, contributing to deforestation. | Unsustainable |

| 2. Brick Kiln Method | A small brick kiln is constructed to regulate combustion.Wood is stacked inside, and controlled burning is done with limited oxygen.The process improves carbonization efficiency and produces higher-quality charcoal. | More efficient than earth mounds.Reduces wood wastage.Less air pollution compared to open burning. | Improve efficiency but still depend on forest resources. | This method is an improvement over the traditional earth mound system. |

| 3. Metal Kiln Method (Semi-modern Approach) | Large metal drums (kilns) are used to burn wood in a low-oxygen environment.The reusable drum makes it more sustainable than traditional methods. | Semi-modern method used by some producers who have access to metal drum kilns.Faster carbonization and produces uniform, high-quality charcoal. | Improve efficiency but still depend on forest resources. | The drum can be sealed and reused multiple times, making it more sustainable than traditional methods. |

| 4. Retort Kiln Method (Modern Approach) | A controlled chamber (retort) heats wood externally, turning it into charcoal with minimal smoke.The gases released can be reused for energy production. | This method is being promoted as an alternative.High charcoal yield (up to 35% of original wood weight).Significantly reduces emissions. | This method is not widely used | This method is more sustainable, can be integrated with sustainable alternative biomass sources like bamboo and agricultural residues. |

While traditional earth mound methods remain the most commonly used, they are highly unsustainable. Brick kilns and metal kilns offer improved efficiency but continue to rely on forest resources. Retort kilns, particularly when utilizing alternative biomass sources like bamboo and agricultural wastes present the most sustainable long-term solution.

Uses of Charcoal

Charcoal is a traditional fuel after firewood, and is mainly used for cooking in urban as well as in rural areas. It was also a raw material for running steam engines in earlier times. It is also used in Ferro-Quartzite Industries. Additionally, charcoal is widely used for space heating during the winter season. Goldsmiths use charcoal for designing and carving of jewellery and blacksmiths for making local traditional tools and implements like spade (moh khiew), knife (wait), lock and keys etc. Charcoal is also used for ironing clothes in households and small laundry units.

Important regions where charcoal is produced

Charcoal making is widespread in the West Khasi Hills, East Khasi Hills and Ri-Bhoi Districts. Additionally, a significant amount of charcoal is generated as a by-product of sawmills and furniture workshops.

Major markets for Charcoal in Meghalaya

The primary charcoal markets in Meghalaya are located across various districts. In the East Khasi Hills District, key markets include Iewduh (Shillong), Cherrapunjee, Mawngap,

Pynursla, Laitlyngkot, Smit and Mawkynrew. In Ri-Bhoi District, major markets are found in Nongpoh, Umsning, Byrnihat and Umden. The West Khasi Hills Districts host significant markets in Nongstoin, Mawkyrwat, Mairang, Balat and Sohiong, in Jaintia Hills, the main charcoal markets are Ummulong, Lad Rymbai and Dawki.

Why is charcoal production becoming a major concern in the state?

There is a surge in the production of charcoal in the state due to the Supreme Court of India ( December 1996) order on regulating timber export and development of new industries in Byrnihat as a result of the State’s new industrial policy that utilises Charcoal as a raw material. This led to the increased demand and fairly good income margin, and has encouraged illicit felling of trees for producing charcoal in many districts of Meghalaya.

A survey found that a minimum of 7-10 trees of approximately 70 cm girth and about 20 meter height are required to produce 1 quintal of charcoal. Most of the hardwood used for the charcoal production comes from the degraded and regenerating forests; several hundred hectares of forests are cut down every year in the state for producing Charcoal. Therefore, charcoal making is a serious concern that poses threat to the forests in the state. A field study revealed that the West Khasi Hills District is the major charcoal producing district, producing and transporting more than 60,000 quintal charcoal annually (Lingdoh and Lingdoh, 2023). Based on this estimation, approximately 6,00,000 trees were felled annually. Furthermore, West Khasi Hills District lost 15 lakh ha (13 %) of humid primary forest cover from 2000-2020 (Global Forest Watch).

A study indicated a decline in the number of animals and bird species observed in the compared to the late 1990s. Reports indicate that endangered and vulnerable species like the Hoolock gibbons and Red Panda (locally known as Dkhan-bah by Khasis) and the Indian Wild Water Buffalo (Fauna Diversity, 2017) have been decreasing over the years. Recently, habitat destruction due to unchecked tree cutting and forest fires has also caused a decline in the elephant population, particularly in areas near West Khasi Hills and Garo Hills.

Beyond its threat on forest, the burning of charcoal poses a serious concern on the environment. Charcoal burning produces a blackish residue of impure carbon. As charcoal is second only to wood as a Third World fuel, it is considered a wasteful fuel, as cooking with charcoal uses much more wood than cooking with firewood. Therefore, burning wood to make charcoal wastes energy and causes pollution (Robert 1995).

How is charcoal production connected to Rural Livelihood?

Many rural households depend on Charcoal production as a primary or supplementary source of income, especially in the areas with limited employment opportunities. People in this region cut the trees, burn, produce charcoal and sell in local markets to sustain their families. In addition, charcoal production involves multiple stages- tree cutting, transportation, carbonization, and market distribution – providing jobs to landowners, daily wage labourers, transporters and traders. Nowadays, agricultural productivity is decreasing due to lack of knowledge, poor management of soil and use of age-old technologies. Hence, people opted for charcoal production as a source of livelihood because of easy availability of raw materials, is not affected by climatic conditions, require no initial investment and it also ensures the year round income.

Can Meghalaya find better solutions?

Traditional charcoal making has become an important livelihood for local communities, particularly in West Khasi Hills District. It serves as a source of income for many in areas with limited employment opportunities as it involves various stages of production. However, the losses incurred due to deforestation-biodiversity, soil health and environmental pollution- far outweigh the immediate benefits. The cost of forest loss will increase at a compounded rate, which will have to be borne by future generations. In fulfilling our present needs, we are compromising the needs of our future generations. Hence, there is an urgent need for alternative solutions to charcoal production and livelihood opportunities.

Let’s discuss some of the key alternative solutions that can substitute unsustainable charcoal production:

- Bamboo as a raw material: Bamboo is fast- growing and a highly renewable resource; unlike timber. It can be harvested every year due to its high regeneration capacity. Bamboo makes excellent charcoal, this bamboo charcoal possesses 80-85 % of Carbon, 4.5-6.5 % of ash, and has a calorific value of 6900-7000 Kcal/kg. It has excellent potential for charcoal production to meet rural energy needs for heating and cooking, as industrial fuel, and to make products such as activated carbon. Meghalaya is blessed with rich diversity of bamboo and climatic conditions suitable for its growth. Therefore, bamboo can be used as an alternative raw material for charcoal production to timber.

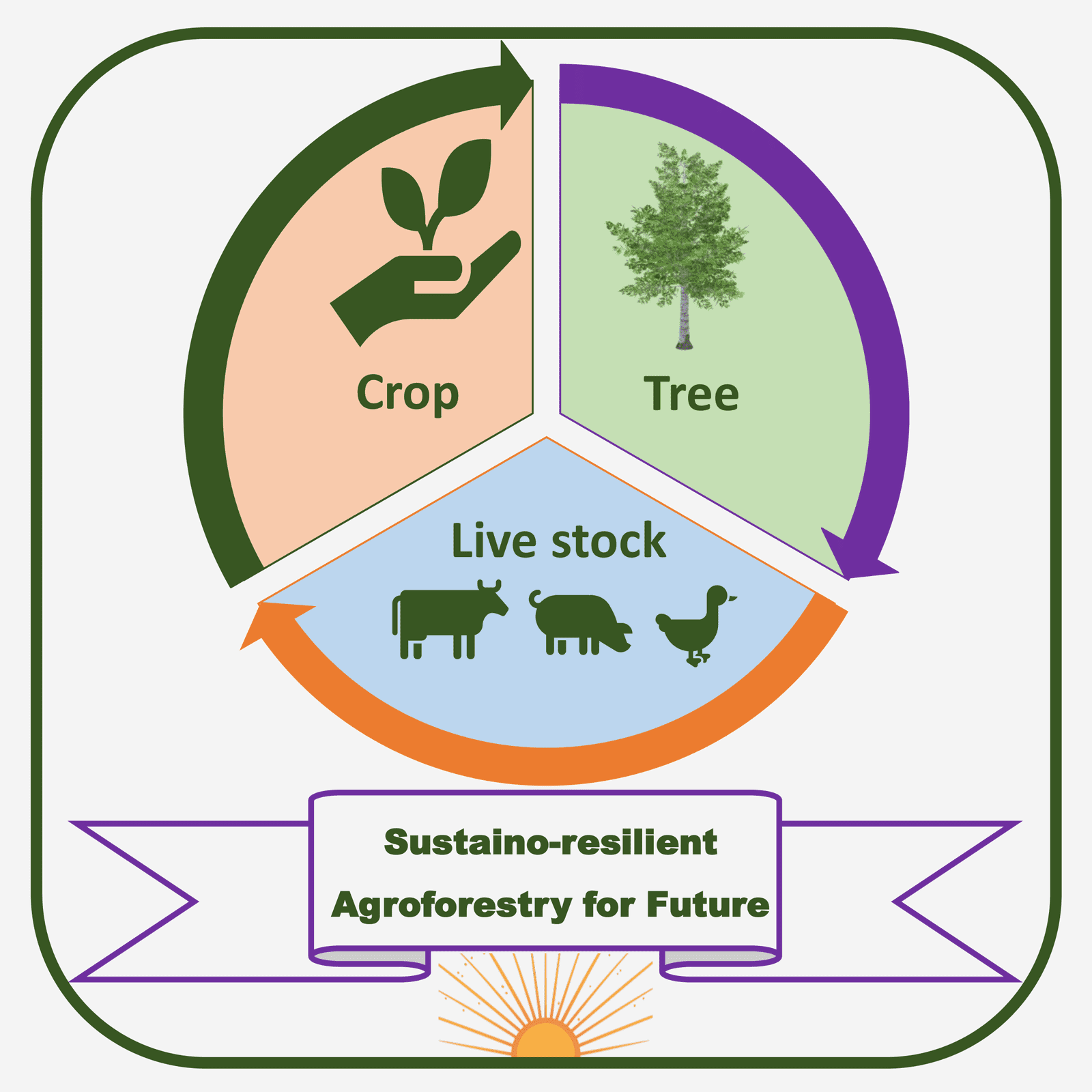

- Agroforestry System: Species selection plays a significant role in production of raw materials under agroforestry systems. Short-rotation, high yielding, and quickly regenerating native tree species grown under agroforestry systems can reduce a pressure on natural forests. In early stages of their production, it improves soil health, supports agro-biodiversity, offers multiple sources of income and provides food and nutritional security.

- Agriculture and other wastes: Rice is the most important food crop and occupies about 44% of the total agricultural land. Maize is the next important agricultural food crop of Meghalaya. It is grown in about 8% of the cropped area and cultivated mainly in the plains of Garo hills, Mairang, Mawphlang and Laskeiñ block of Jaiñtia hills ( CSIR-NEIST). The waste materials generated from agriculture such as Paddy straw and other wastes can be used to produce charcoal briquettes.

- Ecotourism development: Policy makers must promote sustainable tourism by investing on infrastructure development, advertising important tourism spots in social media, newspaper and news. It can attract tourists and generate revenue for the state government. It also provides livelihood opportunities to local communities in direct or indirect ways.

- Value addition of Non timber forest produce (NTFPs): Value addition of NTFPs in Meghalaya can enhance their economic and ecological value while supporting local livelihoods. Medicinal and aromatic plants are processed into herbal teas, essential oils, and various pharmaceutical products. Wild edible fruits like Silver berry, Koronda, black berry, pear, Sohiong and Garcinia are used for making wines, jams, pickles and other value added products. Bamboo and canes are crafted into furniture, handicrafts, and eco-friendly packaging. The wild honey and beeswax are processed into organic honey, candles and medicinal balms. In addition, mushrooms can be dried and packaged for premium markets. The natural resins and gums can be used in cosmetics and varnishes.

Conclusion

The traditional methods of charcoal production in Meghalaya, while providing livelihoods, are highly unsustainable. Over-reliance on forests for producing charcoal is leading to forest denudation and environmental degradation. Therefore, some of the sustainable alternatives such as bamboo charcoal, agroforestry-based wood sources, and modern retort kilns can help reduce the environmental impact while ensuring long-term economic benefits. In addition, community engagement, government policy and financial support, and further research are required to find alternative solutions and achieve economical benefits and environmental sustainability.

Visit our trending blog: https://whereagroforestrymeetsagriculture.com/top-10-profitable-agribusiness-ideas-in-india/

Further reading https://meglaw.gov.in/rules/Meghalaya_Charcoal(Control_of_Production_Storage_Trade_and_Transit)_Rules_2008.pdf

Global Forest Watch. West Khasi Hills, Meghalaya, India Deforestation Rates & Statistics Global Forest Watch.org. https://rb.gy/20qvit. Accessed on 16th March 2025.

Lyngdoh, E. M., & Lyngdoh, A. T. (2023). Environmental Degradation in West Khasi Hills District, Meghalaya. International Journal of Ecology and Environmental Sciences, 49(4), 411-416.