Introduction

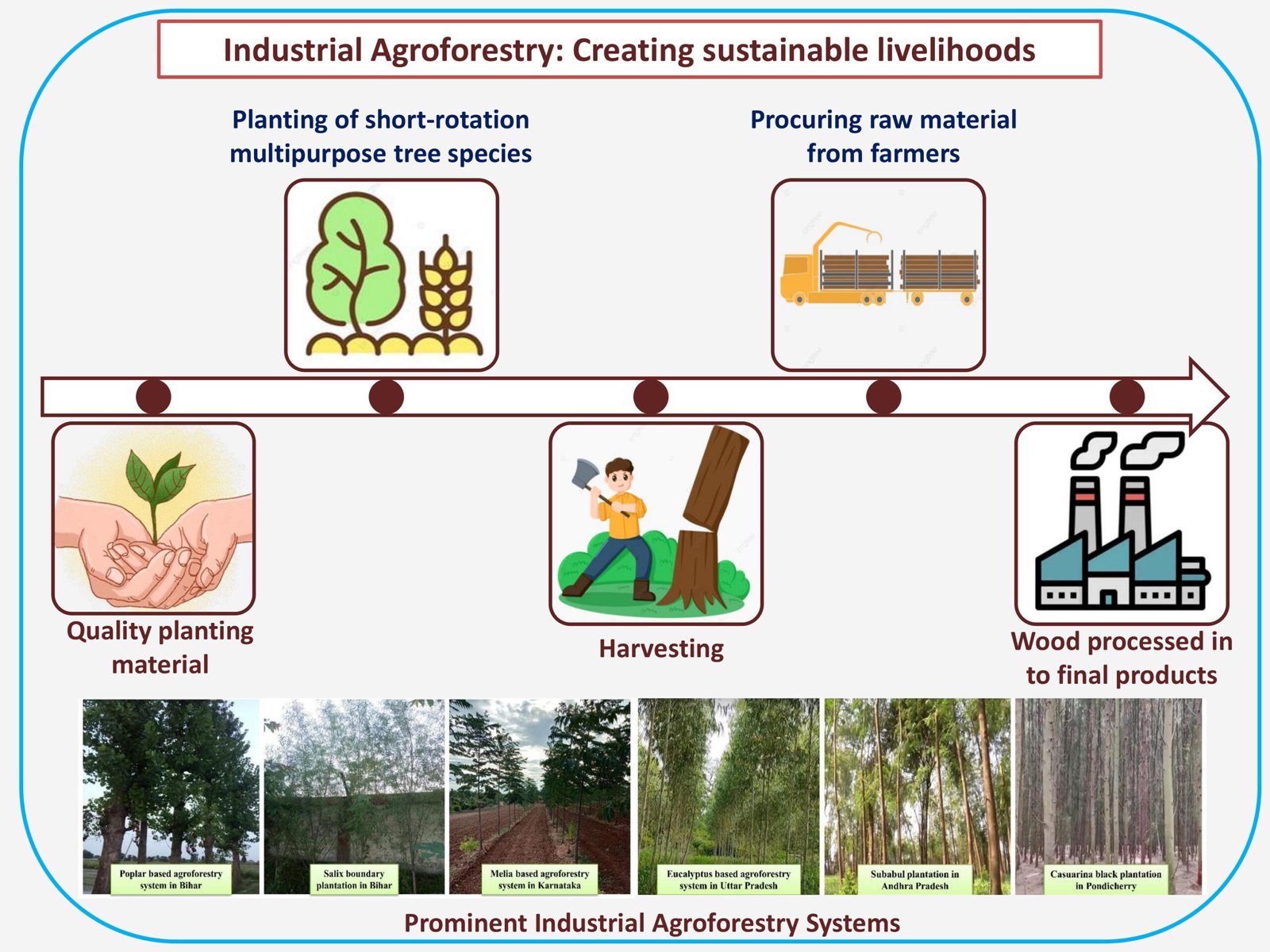

The intentional integration of trees or woody perennials with crops and/or livestock within a production system to produce commercially viable products is known as industrial agroforestry. Sustainable agroforestry practices focus on profitability, productivity, and efficiency without compromising on environmental sustainability, whereas Industrial agroforestry focuses on commercial production. The raw materials generated from these trees are directly and indirectly utilized in wood-based, non-wood-based, and bioenergy industries. In India, there are 14 major wood-based industries considered organized sectors, which include pulp, paper, veneer, plywood, match wood, sports goods, agricultural implements, construction, and miscellaneous industries (Parthiban et al. 2021). In addition to these industries, there are several non-timber product industries such as beedi, lacquerware, brooms, essential oils, katha and cutch, tannins, resin and rosin, cane and bamboo furniture, herbal medicines, cosmetics, bioenergy, etc (Mehta, 2008). Among wood-based industries, the paper industry is the major industry and it’s one of the fastest growing industries in India, which grew at a compounded annual growth rate (CAGR) of 6.7 % over FY 2006-11.

Low forest cover, poor productivity, legal restrictions, and a growing population created a demand for timber and non-timber forest products, and new policy changes and increased industries further ushered imbalance in demand and supply. The mismatch in demand and supply of forest products pushed the country to rely on imports. This has attracted increasing attention towards agroforestry. To meet this growing demand for wood products, conserve natural forests, and reduce imports, India came up with a wood-based National Forest Policy (NFP) in 1988. The NFP, 1988 directed all wood-based industries to rely upon raw materials generated by them by linking farmers, extending technology and market support. However, these directives were not taken seriously, and agroforestry was limited to growing trees on bunds and wastelands. Again, agroforestry got importance through a new policy ie. New Policy on Agroforestry, 2014 to meet the raw material requirements for domestic consumption as well as industrial utility.

India’s wood demand is estimated to vary from 58 Mm3 /annum in 2005 to 153 M m3 /annum in 2020, however, its supply is projected to increase from 29 Mm3 to 60 Mm3 in 2020 (TN). Therefore, India’s wood supply still witnesses a timber deficit of 70Mm3. According to The Forest Survey of India’s (FSI) report, there is a gradual but significant increase in potential wood production from Trees Outside Forests (TOFs). Currently, forests are meeting around 4% of total wood demand, imports around 6%, and the rest is from Trees outside the forest (Tofs). Though TOFs are increasing, India heavily depends on imports. India’s import of forest products amounted to $666.59 million in 2021( International Trade Administration). The United States of America (USA) is the major destination for India’s wood products imports. Therefore, there is a high demand for increasing raw materials for wood-based industries through Agroforestry, which can be a sustainable solution for meeting growing demand while keeping ecological balance in mind.

Types of Industrial Agroforestry Systems

- Industrial Wood Based Agroforestry: Paper and paper board, Newsprint, Construction Industry, Furniture, Packaging, Rayon grade pulp Automobiles, Agriculture implements, Railway sleeper, sports goods, handicraft, plywood, veneer particle board, MDF board, matchbox, pencil industry, etc.

Based on the demand the species are harvested. They are classified as:

- Short rotation species: Used for pulp and paper industries, packaging, sports, plywood, match, and other miscellaneous industries.

- Medium rotation species: Used for handicrafts, packaging, plywood, matches, sports, and other miscellaneous industries.

- Long rotation species: Used for furniture, agriculture implements, and many other construction works.

- Industrial Non-Wood Based Agroforestry: Beedi, lacquerware, brooms, essential oils, Katha and cutch, tannins, resin and rosin, cane and bamboo furniture, herbal medicines, and cosmetics.

- Bioenergy Agroforestry: Firewood, Treethanol, Biodiesel, Biogas, Briquettes, Charcoal.

1. Industrial Wood Based Agroforestry

The report submitted by a High-Level Expert Group constituted by the 15th Finance Commission reported that consumption of wood was 65 million cum of which 3 million cum was produced from forests, around 47 Million cum was produced from plantations (mainly agroforestry systems), and the balance 15 million cum was imported (2017). This clearly shows that around 1/4th of the industrial wood demand is met from imports, and the balance demand is met through domestic production ~94% is from trees outside the forest, mainly from Agroforestry.

- Paper Industry: The paper industry is the only more organized industry in India. It was commissioned in 1832 in Serampore, West Bengal. The raw materials utilized for making paper are wood, agro-residues, and recycled or waste paper. Rags and waste paper were the source for producing paper in 1867, gradually changing to the use of nonwood fibers in 1882. Further, the Forest Research Institute(FRI) gave impetus to the paper industry in India by developing bamboo pulp processing during 1922-24. However, the paper industry took a setback during the 1980s due to the National Forest Policy (NFP, 1988) and the Supreme Court directed companies to use raw materials grown in private lands. After decades of R and D, paper industries are promoting the cultivation of pulpwood species through social or agroforestry models; nearly 80% of wood comes from wood farm forestry. Over an estimated 1,25,000 ha area is contributing to tree cover, additional income for farmers, and creating employment in rural areas. Some of the important companies that came forward to establish farm-industry partnerships are the ITC, JKPM, IP-APPM, etc.

- Wood-based Panel Industry: It comprises plywood, Particleboard, and medium-density fiberboard (MDF), the Indian Plywood & Panel Industry, comprising approximately 3,300 units, primarily operates in the unorganized sector, contributing to the livelihoods of around 1 million people and boasts a market worth approximately Rs. 25,000 Crores. Century Plyboards India Ltd. and Greenply Industries Ltd. command over 50% of the organized market. To meet the domestic demand is met by imported raw materials from Indonesia, Malaysia, Thailand, and China.

- Safety matches: The main raw materials used for making safety matches are Bombax ceiba, Evodia roxburghiana, Ailanthus malabarica, and Hevea brasiliensis. The majority of the matchmaking units are small and cottage industries, over 2/3rd of matches are produced in 2 districts of Tamil Nadu ( Ramanathapuram and Tirunelveli). Kerala is the major source of raw materials to these districts, where nearly 400 small-scale units supply veneers and splints for these industries.

- Furniture and crafts industry: India’s furniture and handicraft sector is largely in the unorganized sector. Hence, there is a lack of data on how many small and marginal enterprises there are, however, there are a few well-known furniture/ handicraft clusters located in Saharanpur, Jodhpur, Channapatna, etc. Teak, Sheesham, Mango, and Mahogany are the common species used in the crafts industry, while some highly expensive items are made of Sandal, Rosewood, walnut, and Oak. In the furniture and crafts industry, teak is the dominant species used( 50%) followed by Mango, Mahogany, and Sheesham ( 30%) and Sal (20%). Some of the regions are well known for their crafts: Saharanpur for intricate wood carving, Rajasthan for colorful Kathputlies (wooden puppets), Hoshiarpur for wood inlay and lacquer work, Natungram for wooden dolls inspired by mythology, Channapatna for wooden toys using vegetable colors, Mysore for rosewood inlay work, and Madhya Pradesh for tribal masks. Each area boasts unique artisanal traditions passed down through generations.

- Sports goods: The sports goods-making industry is a new industry located in the Northwestern part of the country due to easy accessibility to raw materials. The source of raw materials is willow, cane, mulberry, maple, ash, and rosewood ( Tiwari, 1995).

- Musical instruments: The flute, a typical Indian musical instrument, is crafted from bamboo. Rosewood (Dalbergia latifolia) and red sandar (Pterocarpus santalinus) are commonly used in the production of musical instruments.

| Utility | Suitable spp. |

| Furniture and crafts | Redsander,Teak, Sheesham, Mango, Mahogany, Sandalwood, Rosewood, Walnut, Cedar, Sal and Oak |

| Paper and pulp | Eucalyptus spp. Casuarina equisetifolia, Subabul, Bamboo |

| Plywood | Eucalyptus spp. Melia dubia, Toona ciliata, Neolemarkia Kadamba, |

| Match sticks | Ailanthus spp. Albizia falcataria, Boswellia serrata, Alnus Hevea brasiliensis, Ceiba pentandra, Melia dubia, Bamboo, Simarouba glauca, Gmelina arborea |

| Sports goods | Willow, Cane, Mulberry, Maple, Ash and Rosewood |

| Musical instruments | Rosewood (Dalbergia latifolia) and red sander (Pterocarpus santalinus), Bamboo |

(Source: NCCF policy paper 2021)

2. Industrial Non-Wood Based Agroforestry

It is estimated that NTFPs worth Rs. 350 billion are used annually in India and the government revenue from NTFPs is around Rs. 20 billion, nearly 50% of the total forest revenueTotal NTFP exports (raw material as well as finished products) were estimated to be US$ 480 million in 1991 (GoI 1999) (Saigal and Bose, 2003).

- Gum: It is one of the most valuable non-timber forest products in India and exudes from the stems or other parts of trees either naturally or from the injury to the bark or stem. The most important gum is Karaya, obtained from Sterculia urens or S. villosa trees. Maharashtra is the leading producer of gum, which contributes around 30% of total production ( State of Forest Report, 2021).

- Lac: Lac, derived from the secretions of the small insect Laccifer lacca Kerr., is harvested primarily in India, where it serves as a vital component of various lac products. Despite India’s historical significance in lac production, the current output stands at around 15,000 metric tonnes, significantly lower than the peak of 91,199 metric tonnes recorded between 1978 and 1979. The traditional industry of lacquerware and lac turnery, deeply rooted in lac, employs a substantial portion of the workforce in areas such as Channapatna Taluk of Karnataka, where it’s estimated that over 35% of the labor force is involved in lacquer-related activities (Bahuguna and Shiva 2002).

- Katha and cutch: These are the products obtained from the heartwood of Acacia catechu. Katha is used in chewing confectionery, whereas cutch is for dying canvas and tanning leather.

- Bamboo products: Bamboo supplies raw materials for making handicraft items such as table mats, trays, bamboo baskets, etc. These industries are mainly cottage industries, providing livelihood opportunities to many tribal groups ( Banjaras, Bansforias, Kamaras, Kotwalias, etc.) (Aman, 2020).

- Rattan (Cane): Rattan extraction and utilization in India primarily operates as a cottage industry, with approximately 2,000 small to medium-sized industrial units. These units employ over 200,000 individuals, with some engaged in crafting handicraft items and furniture, while the majority work in rural areas involved in extraction, cleaning, processing, and transportation.

3. Bioenergy Agroforestry

Integration of trees in AFS offers feedstock for the production of various forms of bioenergy. Solid biomass is a source of wood fuel, such as charcoal, and the generation of electricity. The oil-producing trees can be utilized in the production of biodiesel, while lignocellulosic biomass can be used to produce bio-ethanol. In addition to this, residues such as leaves and oilseed cake can be utilized in biogas production. Wood fuels are the sole source of energy for low-income poor people who are living in remote and hilly areas. Currently, the biomass productivity per unit area is less than 2 tons per ha per year. Agroforestry practices have demonstrated that this could be safely increased to 10 t ha-1 yr-1 by carefully selecting tree-crop combinations.

| Utility | Trees |

| Biodiesel | Jatropha curcas, Pongamia pinnata, Calophyllum inophyllum, Simarouba glauca, Azadirachta indica. |

| Treethanol | Poplar, Willow, and Eucalyptus |

(Source: Dinesha, 2023)

Planning and Designing Industrial Agroforestry System

Species selection and management

The perennial nature of trees and long gestation period discourage the farmers from going for an agroforestry system, and breeders to take appropriate tree improvement programs. For commercial agroforestry, clone-based superior genetic stocks are necessary to increase productivity and uniformity. For example, clone-based superior genetic stocks developed from TNAU have made a significant impact on productivity which increased from 10 m3/ha/yr to 25 m3/ha/yr. These clones are also suitable for short-term harvesting (16-18 months) for pulp and paper utility and long-term harvesting( >48 months) for plywood utility. India is divided into 15 agro-climatic zones and it hosts 86 % of small and marginal lands with less than 2 hectares. Therefore, multifunctional, short rotation, uniform maturity and high-yielding trees suitable for different agro-climatic conditions are required features for establishing commercial or industrial agroforestry that ensures daily and diversified income to the farmers.

Characters of trees suitable for Industrial Agroforestry

- Short rotation for the pulp and paper industry, long rotation matured trees for plywood, furniture, and crafts-based industries.

- Multipurpose trees

- High yielding

- Uniform clones

The technology used for the production of Quality Planting Materials:

High yield and uniformity are at most important attributes required in the production of quality raw materials for the industries. The technology used to improve these attributes are species/ clonal selection and mini clone technology/ root trainer technology.

Clonal technology

- Selection of candidate plus trees: Large numbers of candidate plus trees (CPTs) were selected from the seed-based Eucalyptus plantations based on their morphological features.

- Cloning: Cloning of each selected tree through vegetative propagation.

- Transfer to clonal Multiplication area: Planting and maintenance of each clone in a vegetative multiplication garden or clonal multiplication area for the production of suitable shoots for cuttings.

- Field testing: Field testing of all clones in replicated field trials on sites and climatic conditions similar to the proposed future planting areas to assess the comparative gene quality and adaptability of each clone.

- Selection of superior clones: Superior clones are selected based on desirable qualities including productivity, disease/pest resistance, timber quality, and quality of bol,e, etc. based on field trials.

- Multiplication of clones: Large-scale production of clonal planting stock of each selected clone and deployment in plantations.

Mini clonal technology:

This technology is developed by Tamil Nadu Agricultural University for clonal mass multiplication (Parthiban, 2017).

Steps:

- Selection of clones: This is the first step in clonal propagation, here individual trees are selected based on their phenotypic characteristics like high yield, disease, and pest resistance, adaptability, timber quality, etc. Overall, superior trees are selected from the plantation through the check method or comparison method.

- Felling and Coppice induction: selected trees are cut at the base (>15 cm) and are allowed for coppice. Shoots are harvested, treated with root hormone, allowed for multiplication, and then superior clones are selected after extensive field evaluation.

- Clonal Multiplication: Superior clones selected from the above process are mass multiplied by mini clonal technology. Selected clones are multiplied by shoot tip culture through micropropagation. The shoots are induced rooting under the mist chamber.

- Mother clonal garden: The above-rooted shoots are planted in the mother clonal garden.

- Apical shoot cuttings: After 30 days of planting of the mother plant, shoot cuttings can be collected and treated with 2 % Carbendazim solution.

Advantages of mini cuttings:

- Increased rooting percentage

- High-quality root system

- Uniform growth in the field

- Reduced gestation period

- Less area required

- No growth hormones are required

List of high-yielding clones

| Species | Utility | Spacing (m) | Population density/ha | Region |

| Casuarina (MTP-2) | Paper/pole | 1.5*1.5 | 4425 | Tamil Nadu |

| Eucalyptus (EC48) | Paper/Biomass | 3*1.5(Dryland)2*2 (Irrigated) | 22503000 | |

| Melia dubea (FCRMID26) | Paper | 1.5*1.5 or 2*2 | 2250-3000 | |

| Melia dubea (MTP1) | Plywood | 5*5 | 400 | |

| Subabul (FCRILL15) | Biomass power | 1.5*1.5 | 4425 | |

| Dalbergia sissoo (DS18) | Biomass power | 1.5*1.5 | 4425 | |

| Ailanthus (MTPAE17) | Match/splints | 5*5 | 400 | |

| Neolamarckia cadamba (FCRA 13) | Matchwood /plywood | 3*3 | 1110 | |

| Gmelina arborea(FCRISS) | Timber | 5*5 | 400 | |

| Populous deltoides (G-48) | Matchwood | 5*5, 5*4, 4*4 | – | UP, Uttarakhand, Punjab and Haryana |

| Populus deltoides (WSL22) (WSL39) | Matchwood | Varies | – | |

| Eucalyptus | Paper | 8.5*1 | 2000 | AP and MP |

| Leucaena | Paper and Pulp | 1.2*1.2, 1.5*1.0, 1.5*1.2 and 1.0*3.0 | – | Gujarat and Maharashtra |

| Melia dubea | Paper, Plywood, and Timber | 5×4, 5×5,6×6, 8×2 | 500, 400, 277 and 625 | Recommended to KA, AP, TN and Telangana |

Design considerations for maximizing productivity

The focus of industrial agroforestry is increasing profit, productivity, and efficient utilization of resources. Therefore, sufficient spacing should be given for agriculture crops in between trees to avoid competition for light, water, and nutrients.

ITC has developed an “Agroforestry Model” with a series of experiments. In this model, pulpwood trees are planted in either single or double rows (1.5 m in between two rows) with a gap of 8.5 m apart and 1m within the lines of trees. It allows maximum sunlight for crops, which are grown in between the rows of trees. This model accommodates 2,000 trees/ha without compromising on wood productivity. This wider spacing allows manual and mechanical operations throughout 4 years of cycle. The trees are accommodated in 25% of the land and crops are in 75% of the total land, which allows farmers to take crops throughout the 4-year interval (Kulkarni 2014). Since 2010, this novel industrial agroforestry model has been established on 6,500 hectares in different parts of Andhra Pradesh and Madhya Pradesh.

Some Successful Industrial Agroforestry Models in India

| Region | Agroforestry Model | Utility | Nearest major industries |

| North West India (Haryana, Punjab, and western UP) | Poplar based Agri-silvicultural system | Plywood, paper, matchsticks, etc. | WIMCO.Ltd. |

| Western India (Rajasthan and Gujarat) | Melia azedarach based agri-silvicultural system | Plywood, paper, | JK Papers |

| Southern region(All southern states) | Melia dubia based Agri-silvicultural system(TN, KA, AP, Telangana, Kerala). | Packing cases, match sticks, plywood. | ITC Paper and Pulp |

| Sapota-Eucalyptus based horti-Silvi-pastoral system for degraded lands (KA) | Pulp and medicinal purposes | Harihar Polyfibers industries | |

| Block plantation of sandalwood | Wood carving, oil extraction, perfume and medicine | Karnataka Soaps and Detergent Ltd. | |

| Teak based Agri-silvicultural system (KA). | Furniture and agricultural implements, | Karnataka Saw Mill Wood Industry | |

| Block planting of Burma bamboo ( Entire western Ghats and coast). | Used in sericulture and ethanol production etc. | Mysore Paper Mills Limited | |

| Coconut-based Horti-pastoral system (Kerala, KA, TN, and AP) | Oil extraction and coir industry. | Coir Development Board | |

| Leucaena leucocephala- silvi-pasture system (TN) | Pulpwood, plywood, packing. | TN Newspapers and Print Ltd. | |

| North and Central region(UP, MP, Chattisgarh, Maharashtra) | Bamboo Agri-silvicultural system ( UP, MP, and MH) | Pulp and paper, charcoal, baskets etc. | Bamboo ram Agri.Pvt.Ltd. |

| Teak based agri-silvicultural system (MH) | Timber | Many unorganized small industries | |

| Shisham-based agri-silvicultural and silvi-pastoral systems | Timber and fuel wood | Sheesham Furniture | |

| Eastern Region (Bihar, Jharkhand, West Bengal and Odisha) | Alder-based agri-Silvi-horticultural system (WB) | Woodcraft, furniture and charcoal | West Bengal Forest Development Corporation Limited |

| Dalbergia sissoo based Agri-silvicultural system( Bihar and Odisha) | Furniture industries | Bihar timber | |

| Gmelina and Eucalyptus-based agri-Silvi-horticultural system (Odisha and WB) | Paper and pulp industry | JK Papers | |

| Mango based Agri-horticultural system (Odisha) | Juice and canning industry | Juice and canning industry | |

| North Eastern region | Agar based Agroforestry system | Agar oil | Ajmal Perfumes |

| Alder-based agri-Silvi-horticultural system | Woodcraft, furniture and charcoal | Alder Furniture | |

| Bambusa balcoa based agri-silvicultural system | Pulp and paper | Cottage industries |

Economic Analysis and Market Opportunities

- Cost-benefit analysis of industrial agroforestry

Factors like land acquisition, labor, equipment, and maintenance expenses need consideration. Timber farming yields long-term returns but requires patience for trees to mature. Agriculture offers immediate income but demands regular investment in seeds, fertilizers, and labor. Balancing both can diversify revenue streams, mitigate risks, and optimize land usage for sustainable profit in the long run.

Case study 1: JK Paper: Creating sustainable livelihoods through industrial agroforestry

JK Paper is located in Gujarat, Telangana, and Odisha. It produces paper via pulp obtained from agroforestry and social forestry and distributes 50 million high-yielding tree saplings annually (hybrid seeds of Subabul hybrid (K-636, K-8, and Kranti), Casuarina hybrid, Eucalyptus camaldulensis, E. pellita, E. urophylla, and E. grandis to the farmers at a subsidized rate. More than 75,000 farmers engaged in agroforestry, accounting for 5 lakh acres of tree planting. In addition to this, it is also involved in the transfer of technology to planting and maintaining farms. It guarantees farmers assured prices at the prevailing market price and a buy-back system, which procures raw materials from farmers. The hybrids of Subabul, Casuarina, and Eucalyptus are planted with Cotton, Rice, and Wheat at the spacing of 3×1 m, 2×1 m, and 1.5×1.5 m.

Economics:

| Particulars | Subabul (Rotation 3 years) | Cotton (1 year) |

| Total investment (E) | 12,500 | 28,140 |

| Total yield | 35 MT | 1.5 MT |

| Sale price/MT | 3,200 | 40,000 |

| Total revenue | 1,12,000 | 60,000 |

| Firewood/ Cotton waste | 5,000 | 2,000 |

| Total revenue (Rs) | 1,17,000 | 62,000 |

| Net Income(E-R) per acre | 1,04,500 | 33,860 |

| Net income per acre per year | 34,833 | 33,860 |

(Source: Agarwal et al. 2017)

- Value-added products and market potential

Agroforestry offers raw materials for wood-based industries such as pulp and paper, furniture, handicrafts, etc., non-wood-based products, and also biomass, seeds, and other residues for bioenergy production.

Case study 2: Sustainable Value Chain Development for Industrial Agroforestry: A Tamil Nadu case study

The success of any farming system depends on the forward and backward linkage. The whole country is busy focusing on Agroforestry models without considering real constraints such as quality planting material, licensing, marketing, and technological intervention. In this scenario, Tamil Nadu becomes a role model for the whole country by developing a sustainable value chain system for Industrial Agroforestry focusing on backward and forward linkage. First, TNAU analyzed the real constraints in production, processing, and marketing systems. It developed high-yielding clones and maintained uniformity through mini-clone technology, established various suitable agroforestry models, designed and developed debarking and chipping machines, and focused on value-addition technology of agroforestry residues into briquettes. For forward linkage, it deployed contract tree farming, which incentivized the farmers through technology transfer, buy-back system, and assured price.

Case study 3: A case study on Biofuel Agroforestry

The Karnataka State Bioenergy Development Board (KSBDB) was established by the Karnataka government to promote biofuel production and consumption in the state. It started a Biofuel program to produce Biodiesel from non-edible oils extracted from seeds of oil-bearing trees such as Pongamia pinnata (Pongamia), Azadirachta indica (Neem), and Simarouba glauca (Simarouba) that can be grown in the small and marginal landholdings under agroforestry systems. Under the Program, KSBDB was involved in improving planting material and designing practices and also focused on forming linkages between villages by establishing Information Dissemination Centers (IDC). Now farmers by forming cooperatives and Farmers Producer Organization (FPO), and women Self Help Groups (SHG) are expanding the oilseeds processing facility. The villages with processing capacity are crushing 80% of the seeds they procure. They are also making use of other value-added products to meet their requirements, biofertilizers and de-oiled cake, and selling locally to the consumer. The income generated from oilseed trees for Biofuel is stable and predictable, essentially making it a ‘reserve’ cash source for the farmers.

Biofuel Park in Tinthani, Yadagiri, Karnataka

It was established in 2012 working under UAS Raichur covering 42 acres of land, initiated with the funding support of the Karnataka State Bio-energy Development Board (KSBDB). The seeds and seedlings (50,000) of Pongamia, Neem, Simarouba, etc were distributed to farmers free of cost. There is a 60-70 % survival rate of seedlings in farmers and expected to yield in 3-4 years. Currently, Pongamia seeds are procured from farmers at Rs 32/kg. It is involved in training programs such as processing of oil, use of fuel as tractor fuel and lighting lamps, and utilization of seeds for byproducts like seed cake.

Species planted: Pongamia, Neem and Simarouba, Madhuka, Melia etc.

Spacing maintained: 5*5 m, 4*4 m, 6*6 m

clones of Pongamia: 3*3 m

- Economic incentives and policy support

The Indian government has implemented various economic incentives and policy support measures to promote agroforestry, recognizing its potential for sustainable development and environmental conservation. Some initiatives include:

Submission on Agroforestry: Provides seedlings at a subsidized rate for high-density and low-density block planting and boundary planting. Demonstration of Agroforestry Models and capacity building and Training to the farmers.

National Transit Pass System: Recently, the Ministry of Environment, Forestry, and Climate Change launched the “One Nation One Pass” regime for seamless transit of timber, bamboo, and other forest produce across the country.

Indian Forest and Wood Certification Scheme: It offers third-party certification designed to promote sustainable forest management and agroforestry in the country. It can provide market incentives to various entities that adhere to responsible agroforestry practices in their operations.

Carbon credit and green credit: These are the incentives given by the central government for tree plantation and reducing CO2.

PM-JIVAN: Pradhan Mantri-Jaiv Indian Vatavaran Anukool Fasal Awashesh Nivaran, was launched to provide viability gap funding to provide initial thrust to create 2G ethanol capacity in the country and attract investment. Financial support of 1969.50 cr was given from 2018 to 2023.

Biodiesel Purchasing Policy: GoI released a policy on Biodiesel purchase and it helped to connect biodiesel manufacturers to oil companies. It clearly defined the source for biodiesel should be non-edible oils and vegetable oils. Priority will be given to biodiesel producers who propose to use non-edible tree-borne oils such as Jatropha, Pongamia, etc. It also directed the Panchayats to establish Rural Business Hubs (RBH) in collaboration with private agencies for industrial processing.

Challenges and Limitations

- Quality Planting Material: Industrial agroforestry relies heavily on High Yielding Varieties (HYVs) with uniform clones to ensure consistent and high yields. However, the long gestation period of trees and the lack of sufficient research and development in this area contribute to the scarcity of quality planting material.

- Skilled Workers and Standard Protocols: Effective Industrial agroforestry management requires skilled personnel who understand the specific protocols for planting, tending, and harvesting trees. Standardized protocols for activities such as pruning, pest management, and soil conservation are essential for maintaining the health and productivity of agroforestry systems.

- Lack of Mechanization and Innovation: The absence of mechanization and innovation in agroforestry operations can hinder efficiency and productivity. Manual labor is often required for tasks such as planting, weeding, and harvesting, which can be time-consuming and labor-intensive.

- Aftercare Plantation Management Activities: Proper aftercare and maintenance such as watering, mulching, fertilizing, and protecting young trees from pests and diseases. However, inadequate attention to aftercare plantation management can result in poor tree survival rates and reduced yields in agroforestry systems.

- Tending and Cultural Operations: Tending and cultural operations encompass pruning, thinning, shaping, and training trees to optimize their growth and productivity. However, the lack of skilled labor and standardized protocols for tending and cultural operations can lead to suboptimal tree growth and reduced yields in agroforestry systems.

- Land Tenure Issues: Land tenure issues, such as insecure land rights and conflicting land-use policies, can pose significant challenges to the establishment and management of agroforestry systems. Without clear and secure land tenure arrangements, farmers may be reluctant to invest in long-term tree crops or may face barriers to accessing credit and support services.

- Knowledge and Technical Capacity: Lack of accessible and relevant information such as species selection, plantation establishment, management techniques, and market access strategies, as well as limited extension services, can impede the adoption and expansion of agroforestry systems.

- Market Access and Infrastructure: Inadequate market infrastructure and limited market opportunities can undermine the potential profitability of agroforestry enterprises and discourage investment in tree-based farming systems.

- Licensing and Ease of Transit: In some states, harvesting trees with state importance needs permission and a license for transit to different states. It discourages the farmers from taking agroforestry.

Future Directions and Recommendations

A. Research needs and gaps: Research needs to be focused on developing region-specific Commercial/ Industrial Agroforestry Models, high-yielding varieties, and clones by giving financial support to state universities and research institutes and also encouraging research in Public Private Partnerships (PPP) since many private entities have already taken research activities. ITC developed the standard Agroforestry Model for its decadal experience of research; this kind of standard model can be developed.

B. Policy recommendations: Implement policies that incentivize the adoption of industrial agroforestry, such as tax breaks or subsidies, providing quality planting material free of cost, providing extension services, and subsidies on the purchase of tools and processing units for farmers who integrate trees into their agricultural practices. There is a need to establish an Industrial Agroforestry Board in every state, which can oversee all the activities. Consortium of Industrial Agroforestry in Tamil Nadu and Karnataka State Bio-energy Development Corporation in Karnataka are examples that can be role models for other states. These kinds of Institutional models can be adopted.

C. Scaling up and mainstreaming industrial agroforestry: Focus on selecting suitable tree-crop combinations, optimizing land use, implementing sustainable practices, and leveraging technology for precision farming. Regular extension activities support farmers and partnerships with stakeholders are essential for long-term success. Moreover, fostering a supportive policy environment and investing in research and development are driving forces in achieving innovation and resilience in industrial agroforestry systems.

Conclusion

Industrial Agroforestry is mainly focused on the commercialization of farming systems through the deliberate integration of trees. Based on the utility of trees, Industrial agroforestry is classified as wood-based, non-wood-based, and bioenergy. The paper and pulp industry is mainly organized and largest among all wood-based industries, the remaining are small or cottage industries. Non-wood-based industries such as gum, bamboo, lac, etc. are highly unorganized sectors and these are the main source of income for many rural people. Nowadays, trees based on Bio-energy such as biofuels, briquettes, charcoal, etc. are gaining importance as they are clean and renewable energy sources.

Increasing demand and restrictions on natural forests are pushing industries to look forward to Industrial agroforestry by incentivizing farmers through quality planting material at a subsidized rate, transferring technology, and guaranteeing a buyback system. Many private and government agencies are involved in research and development for developing high-yielding quality planting material by using clonal technology and mini clonal technology, development of standard protocol, and contract forest farming. Some of the examples for these are WIMCO, JK papers, TCS papers, etc. For the success of any industrial agroforestry, there is a need for forward and backward linkage. This can be learned through the Industrial Agroforestry model in Tamil Nadu, which addressed all the constraints by developing quality material, innovation in mechanization and value addition, and helping farmers with the buy-back system by establishing the Consortium on Industrial Agroforestry. Karnataka was the first state to bring a biofuel policy and established the Karnataka State Biofuels Development Board (KSBDB), which helped income generation from oilseed trees and made it a ‘reserve’ cash source for the farmers.

Industrial agroforestry can generate employment opportunities, stimulate rural economies, and enhance market access for farmers, thus driving socio-economic development while preserving natural resources. Moreover, it enhances productivity, diversifies income streams, and promotes resource efficiency. This approach fosters resilience to climate change, reduces soil erosion, and mitigates environmental degradation, ultimately contributing to long-term economic stability and prosperity for communities dependent on agriculture.

In conclusion, Industrial Agroforestry stands as a promising avenue for sustainable agriculture, blending economic viability with environmental stewardship. As we move forward, let’s seize the opportunity to expand its implementation and delve deeper into research, ensuring its integration into mainstream agricultural practices for a more resilient and harmonious future.

References

Agarwal, N.K., Shukla, O.P., Narkhede, S.L. and Chauhan, S.K.S., 2017. Promotion of short rotation agro and farm forestry system in Gujarat and Maharashtra by JK Paper Ltd Unit-CPM. Indian Forester, 143(9), 862-868.

Bansal, A.K., 2021. Sustainable Trade of Wood and Wood-based products in India. NCCF Policy Paper, p. 1-15.

Chavan, S.B., Vishnu, R., Kumar, N., Kumar, D., Sirohi, C. and Handa, A.K., 2021. Melia dubia An indigenous tree species for industrial agroforestry in India. Indian Farming, 71(6).

Dinesha, S. (2023). Short-rotation Tree-based Biofuel Production in India from Agroforestry and Marginal Lands without Compromising Food Security. Journal of Agricultural Technology, 10(2), 58-71.

Dhaka, R.K., Jha, S.K. and Chaudhari, C., Development of Industrial Agroforestry in India. Indian Farmer, p. 1413-1420.

Dhiman, R.C., 2012. Transforming rural Uttar Pradesh through integrating tree culture on farmland: a case study of WIMCO’s poplar program. LMA Convention Journal. 8(1), 85-98.

Jain SK and Singh P., 2000. Economic Analysis of Industrial Agroforestry: Poplar (Populus deltoides) in Uttar Pradesh (India). Agroforestry Systems, 49, 255-273.

Khanna, N.K., Shukla, O.P., Gogate, M.G. and Narkhede, S.L., 2019. Leucaena for paper industry in Gujarat, India: Case study. Tropical Grasslands-Forrajes Tropicales, 7(2), 200-209.

Kulkarni, H.D., 2013. Industrial agroforestry: an Indian tobacco company (ITC) initiative. Indian Journal of Agroforestry, 15(2), 49-54.

Mehta, T., 2008. A Handbook of Forest Utilization. Periodical Expert Book Agency, p. 298.

Parthiban, K.T., 2017. Mini clonal technology for tree crops. Forestry Technologies–A Complete Value Chain Approach, p.103-108.

Parthiban, K.T., Fernandaz, C.C., Sudhagar, R.J., Sekar, I., Kanna, S.U., Rajendran, P., Devanand, P.S., Vennila, S. and Kumar, N.K., 2021. Industrial agroforestry—A sustainable value chain innovation through a consortium approach. Sustainability, 13(13), 7126.

Thank you, I have just been searching for info approximately this subject for a long time and yours is the best I have discovered so far. But, what concerning the bottom line? Are you positive about the supply?

Thank you for taking your valuable time to leave a positive thought, which motivates and encourages us to do more research and continue this journey. Yes, there is a dearth of comprehensive information about this topic and initially, we thought to make it a book chapter, but for the larger good and help to BSc students, we made it a blog. Yes, we are very positive about the supply. Just check the factual information about the contribution of Agroforestry and trees outside the forest (TOF), you can also see the case studies that are mentioned in the blog. If you have further queries, feel free to contact dineshasid100@gmail.com.